Manufacturing an OPQ Box

OPQBox manufacture is done in three steps. First, the PCB has to be manufactured via a PCB board house. Next the PCB has to be assembled with the components soldered to it. Finally the enclosure has to be laser cut and glued together.

PCB manufacture

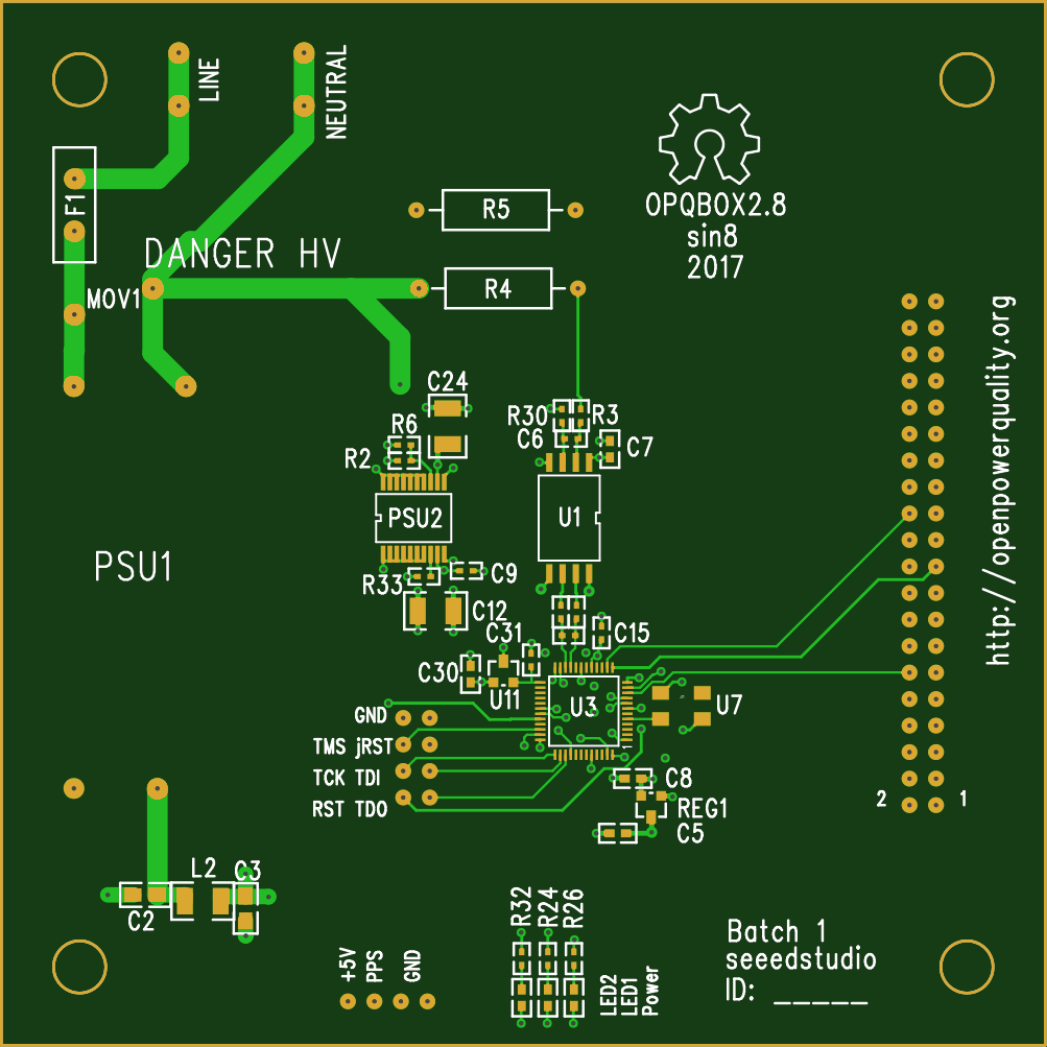

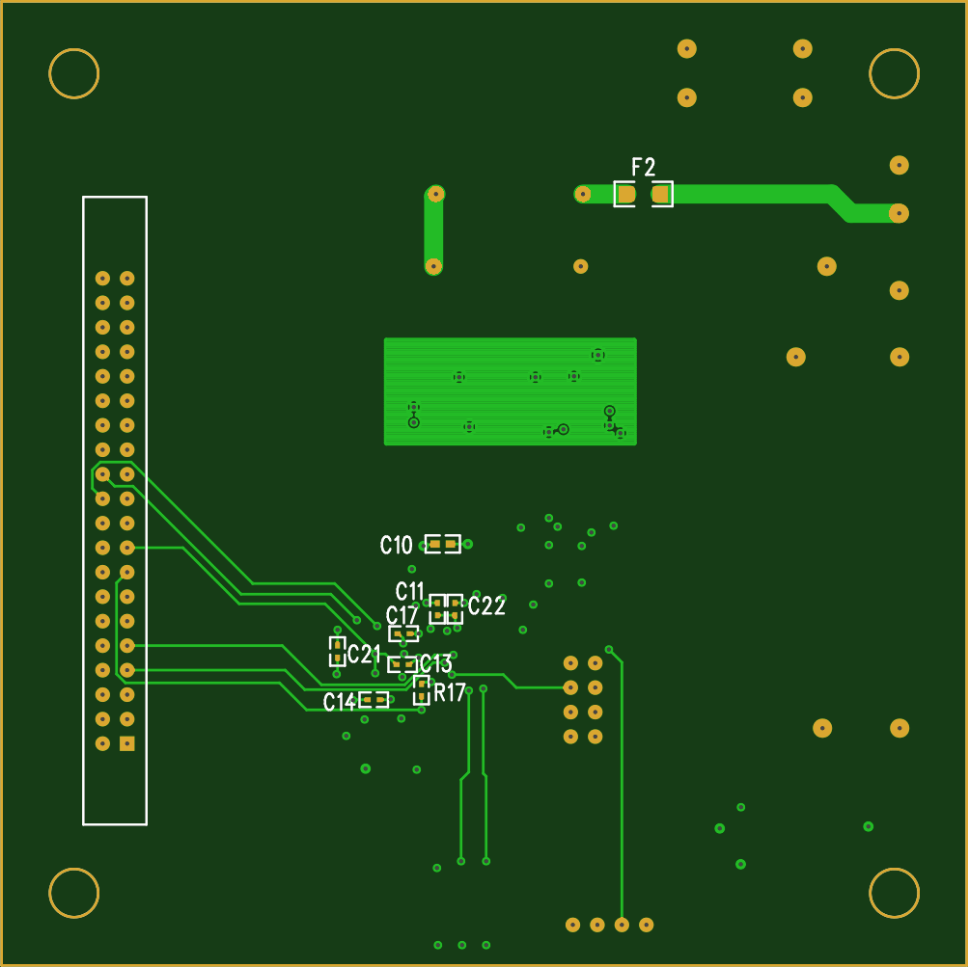

A PCB vendor will require you to provide them with the Gerber files, drill file and PCB dimensions. The PCB is a 4 layer 100mm X 100mm board with minimum trace width of 6 mil. The PCB repository contains the latest Gerbers and drill files here. Additional this directory contains the the component position file, which will be used for assembly. If your PCB board house provides a gerber preview, make sure that the preview looks similar to the images below:

https://github.com/openpowerquality/opq/tree/master/box

If you intend to assemble the PCB yourself you may want to create a stencil using the paste mask gerber layers.

Assembly

The bill of materials for the OPQ box pcb can be found here. It can be supplied to the assembly house for turn key assembly or used with the component supplier to procure the components. Furthermore the Positions file contains the positions and orientations for all components.

Enclosure

The design for the enclosure panels is available here. It is meant for being manufactured from 2mm acrylic sheet. We are working on a PCB re-design which will fit a commercially available enclosure.